Machine Learning in Embedded Systems: A Practical Guide

- BLOG

- Artificial Intelligence

- January 31, 2026

Machine learning in embedded systems refers to running trained models directly on constrained hardware such as microcontrollers. Decisions are made inside firmware instead of relying on fixed rules or cloud processing.

It enables embedded devices to recognize patterns, adapt to variation, and respond intelligently in real time. If you work with embedded products, you have likely seen where traditional logic starts to fail. Thresholds break under noise, signals overlap, and system behavior shifts once devices leave controlled environments.

These aren’t edge cases, they are normal operating conditions in real deployments. The goal here is clarity. You’ll learn when machine learning fits embedded systems, how it changes firmware behavior, and how to avoid common production failures with Webisoft’s guidance.

Contents

- 1 What Is Embedded Systems

- 2 How Embedded Systems Work Without Machine Learning

- 3 What Does Machine Learning in Embedded Systems Mean

- 4 Build machine learning systems for embedded devices with Webisoft.

- 5 How Machine Learning Changes Embedded Systems

- 5.1 From Explicit Rules to Learned Decision Logic

- 5.2 Binary Decisions Become Probabilistic Outputs

- 5.3 Pattern Evaluation Replaces Threshold Checking

- 5.4 Decision Flow Shifts Inside the Firmware

- 5.5 Behavior Becomes Data-Dependent, Not Assumption-Dependent

- 5.6 Execution Timing and Determinism Change

- 5.7 Memory and Resource Planning Change

- 5.8 Testing Shifts From Logic Paths to Data Behavior

- 5.9 Updates and Maintenance Become Model-Centric

- 6 Key Benefits of Machine Learning in Embedded Systems

- 7 The Embedded ML Data Pipeline (Step-by-Step)

- 8 Examples of Embedded Machine Learning

- 9 Hardware Constraints That Shape Embedded ML Design

- 10 Model Optimization Techniques for Embedded Devices

- 11 Embedded ML vs Cloud-Based AI

- 12 Common Challenges and Failure Modes in Embedded ML

- 13 When Embedded Machine Learning Is the Wrong Choice

- 14 The Future of AI in Embedded Systems

- 15 How Webisoft Builds Reliable Embedded Machine Learning Solutions

- 16 Build machine learning systems for embedded devices with Webisoft.

- 17 Conclusion

- 18 FAQs

- 18.1 What programming languages are commonly used for embedded machine learning?

- 18.2 Can embedded machine learning work without an operating system?

- 18.3 Is embedded machine learning suitable for battery-powered devices?

- 18.4 What hardware is required for embedded machine learning?

- 18.5 Do embedded systems need the internet for machine learning?

What Is Embedded Systems

An embedded system is a small, purpose built computer inside a device that controls a specific function. It is not meant for general use like a laptop or phone. Instead, it runs dedicated software that reads inputs from sensors and controls outputs such as motors, switches, or displays.

Most embedded systems rely on rule-based embedded systems logic, where fixed instructions process sensor data and trigger predefined actions. For example, washing machines, microwaves, cars, and medical devices use embedded systems because they deliver predictable behavior, low power usage, and reliable real time control in constrained environments.

How Embedded Systems Work Without Machine Learning

Before machine learning entered the embedded system, it relied entirely on logic written by engineers. Every decision the system can make is defined in advance. Here’s how embedded systems works without ML:

Before machine learning entered the embedded system, it relied entirely on logic written by engineers. Every decision the system can make is defined in advance. Here’s how embedded systems works without ML:

Sensors (Input)

Sensors collect raw data from the physical environment, such as temperature, pressure, light, or motion. These values are typically simple numeric readings captured at regular intervals.

Microcontroller or Processor

The microcontroller acts as the control unit. It reads sensor values and executes instructions exactly as programmed, without interpretation or adaptation.

Firmware Logic

The firmware contains explicit rules written using conditional logic. When a condition is met, a predefined action is triggered. The logic remains fixed unless the firmware is manually updated.

Actuators (Output)

Actuators perform physical actions based on firmware decisions. This can include switching relays, driving motors, updating displays, or activating alarms.

Real-Time Execution

Processing happens within strict timing limits. Responses are immediate and predictable, which makes this model reliable for well-defined and timing-sensitive tasks.

Why This Model Works and Where It Breaks

This structure is fast, efficient, and easy to validate. But it cannot adapt when inputs vary, signals become noisy, or patterns change over time. That rigidity is the core limitation machine learning later addresses.

What Does Machine Learning in Embedded Systems Mean

ML is an intelligent system that allows an embedded system to make decisions from learned data patterns executed directly inside firmware on resource-constrained hardware, instead of relying on fixed rules. It’s also known as TinyML. The embedded hardware stays the same, but the decision logic becomes adaptive. Models are trained offline, then run on the device to interpret sensor data and handle real-world variation more effectively.

Build machine learning systems for embedded devices with Webisoft.

Discuss firmware-level ML design, optimization, and production challenges with our team at Webisoft.

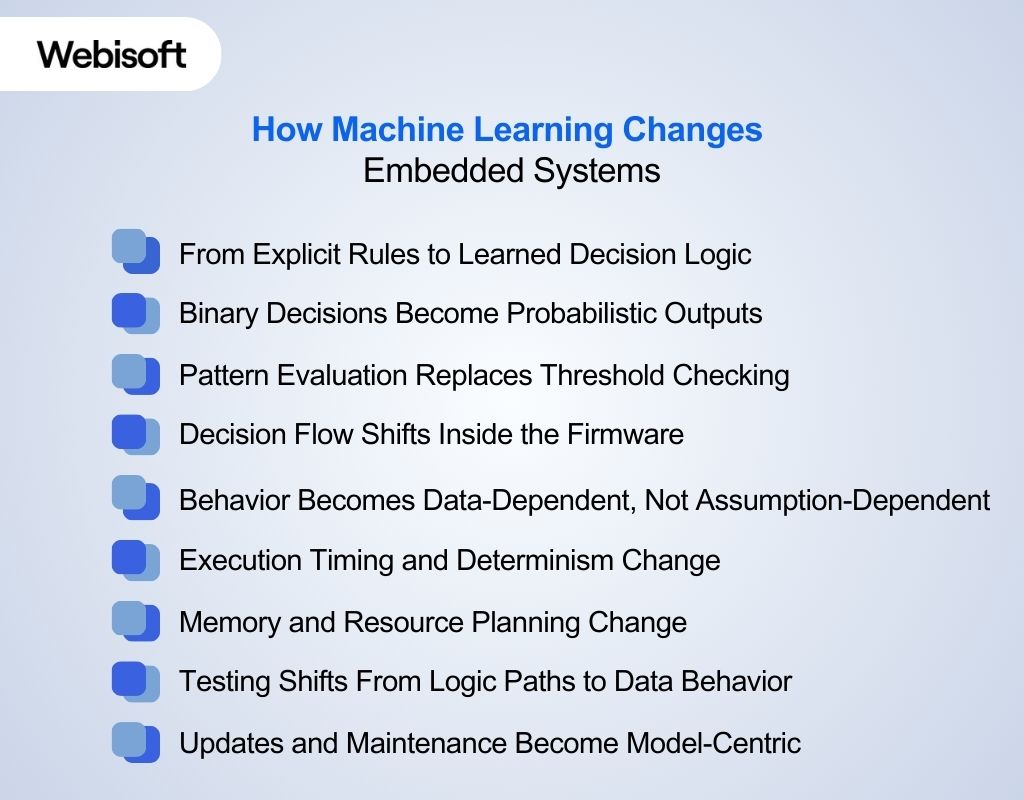

How Machine Learning Changes Embedded Systems

When machine learning is introduced into an embedded system, the hardware remains the same, but the decision mechanism changes fundamentally. Here is how machine learning in embedded systems changes the functionality of the system:

When machine learning is introduced into an embedded system, the hardware remains the same, but the decision mechanism changes fundamentally. Here is how machine learning in embedded systems changes the functionality of the system:

From Explicit Rules to Learned Decision Logic

In a traditional design, engineers define every condition the system can respond to. With machine learning, those conditions are no longer written line by line. The decision logic is learned from historical data and represented as a model. The embedded system executes that model instead of comparing values against static rules. This turns deterministic logic into learned behavior without changing the device’s role.

Binary Decisions Become Probabilistic Outputs

Rule-based systems return yes or no answers. Machine learning models return confidence scores. Instead of deciding whether a signal crossed a threshold, the system estimates how likely a condition is. This probabilistic output allows the system to respond more realistically when signals overlap or fluctuate. That change is central to how ML inference on edge devices works in practice.

Pattern Evaluation Replaces Threshold Checking

Once ML is introduced, the system stops evaluating single values in isolation. It evaluates relationships across time and across multiple inputs. Subtle variations that would look insignificant to threshold logic become meaningful when seen as part of a pattern. This is how embedded systems start detecting conditions that are hard to define explicitly.

Decision Flow Shifts Inside the Firmware

The firmware still controls timing, memory, and hardware access. What changes is the decision layer inside it. Instead of branching through conditional statements, the firmware feeds input data into the trained model and acts on the result. This is where embedded systems move closer to embedded AI, even though the device itself stays constrained and task-specific.

Behavior Becomes Data-Dependent, Not Assumption-Dependent

Traditional systems behave based on assumptions made during development. Machine learning–enabled systems behave based on patterns observed in real data. That difference explains why ML is introduced when rule logic becomes too fragile to maintain.

Execution Timing and Determinism Change

In machine learning in embedded systems, execution timing becomes less predictable. Fixed instruction paths are replaced by inference paths that vary with input data. Engineers must design around worst-case inference time and validate real-time behavior under different conditions, rather than relying on static timing calculations alone.

Memory and Resource Planning Change

When machine learning is introduced, memory planning changes immediately. Traditional systems allocate memory for code and buffers only. ML adds model weights, intermediate tensors, and runtime states that must fit within tight limits.

This is especially visible in microcontroller machine learning, where RAM may be measured in kilobytes. Engineers now design memory layouts around model execution, not just firmware logic.

Testing Shifts From Logic Paths to Data Behavior

Testing no longer focuses only on whether the code runs correctly. Engineers must validate how the system behaves across real input distributions. This includes edge cases, noise, and unseen conditions. In AI in embedded systems, a device can pass functional tests yet behave poorly in production. As a result, test data quality becomes as important as code correctness.

Updates and Maintenance Become Model-Centric

Firmware updates used to change features or fix bugs. With ML, updates can change system behavior without altering hardware or functionality. Updating a model inside firmware-based ML means decisions may shift subtly.

Versioning, rollback, and validation now apply to models as well as code. Maintenance becomes about preserving behavior consistency, not just system stability. This shift in how decisions are made directly affects how embedded systems perform once they leave controlled environments.

Key Benefits of Machine Learning in Embedded Systems

Once ML is added to an embedded system, the system starts performing better in situations where fixed logic usually struggles. Here are a few benefits of using ML-enabled embedded systems:

- Higher accuracy in real operating conditions: ML models handle noisy, incomplete, and overlapping sensor signals better than static rules, reducing false triggers and missed detections.

- Less manual rule design and tuning: Engineers no longer need to spend weeks adjusting thresholds for every edge case as the system behavior is shaped by data.

- More stable behavior across edge cases: Performance remains consistent even when conditions drift over time, such as temperature changes, sensor aging, or varying usage patterns.

- Faster decisions without cloud dependency: Decisions happen locally on the device, avoiding network delays and making the system responsive even when connectivity is limited or unavailable.

- Easier scaling across devices and variants: A trained model can be reused or retrained with new data, allowing similar products to adapt to different environments without redesigning logic from scratch.

- Lower long-term development and maintenance cost: Fewer firmware rewrites, reduced debugging effort, and less operational overhead make ML-enabled embedded systems more economical over their lifecycle.

The Embedded ML Data Pipeline (Step-by-Step)

Before a model can influence behavior, data must move through a clear and structured path inside the device. This is what the embedded ML pipeline looks like at the firmware level, step by step, without abstraction or hype.

Before a model can influence behavior, data must move through a clear and structured path inside the device. This is what the embedded ML pipeline looks like at the firmware level, step by step, without abstraction or hype.

Sensor data capture

The system continuously reads raw signals from sensors such as accelerometers, microphones, cameras, or temperature probes. These readings are collected at fixed sampling rates defined by timing and power constraints.

Preprocessing and windowing

Raw signals are cleaned, normalized, and grouped into time windows. This stage handles noise reduction, scaling, and formatting so the data becomes usable for downstream analysis.

Feature extraction or raw signal input

Depending on the model design, the system either computes features or passes processed signals directly forward. This is where sensor data processing determines what information the model actually evaluates.

Model inference

The prepared data is fed into the trained model stored in memory. The model evaluates patterns and produces an output, such as a classification score or confidence value.

Decision thresholds and actuator control

Firmware logic interprets the model output and decides whether to trigger an action. Motors, relays, displays, or alerts are activated based on defined thresholds and safety rules. This pipeline shows how machine learning fits into embedded firmware in a direct and inspectable way.

Examples of Embedded Machine Learning

Practical examples help clarify where pattern-based decision making becomes necessary. In many devices, fixed logic fails once inputs overlap, drift, or vary across environments. Here are a few examples of how machine learning in embedded systems is applied inside constrained hardware to interpret complex signals:

| Use Case | What the Embedded System Does | Why ML Is Used |

| Smart cameras | Identifies people instead of reacting to any movement | Reduces false alerts from shadows, rain, and lighting changes |

| Keyword spotting on microcontrollers | Detects wake words locally | Enables always-on listening without cloud processing |

| Predictive maintenance | Monitors vibration patterns in machines | Detects early fault signals before mechanical failure |

| Smart thermostats | Learns occupancy and usage patterns | Adjusts control behavior without manual tuning |

| Wearable health devices | Analyzes heart rate and motion signals | Identifies abnormal patterns beyond fixed thresholds |

| Industrial quality inspection | Detects surface defects on products | Finds subtle visual defects rules cannot define |

Hardware Constraints That Shape Embedded ML Design

Machine learning models running on embedded devices must operate within strict hardware limits. Unlike cloud or desktop environments, embedded platforms have fixed memory, tight timing requirements, and limited power budgets. Here’s how:

Machine learning models running on embedded devices must operate within strict hardware limits. Unlike cloud or desktop environments, embedded platforms have fixed memory, tight timing requirements, and limited power budgets. Here’s how:

Memory: Fitting Models in Kilobytes

Engineers fight kilobyte wars. A typical Cortex-M4 class device offers 64KB RAM and 256KB flash. Model weights, tensors, and buffers compete directly with firmware. Once memory usage crosses 70%, deployments often fail. Many vision models start above 1MB and survive only after aggressive quantization, sometimes shrinking to 40–50KB.

CPU: Inference Under Tight Deadlines

On a 168MHz MCU, a 10ms window allows roughly 1.6 million cycles, but control logic, interrupts, and safety checks consume most of it. In practice, ML inference often gets a fraction of that budget. Engineers design models to finish reliably, not optimistically.

Power: Microjoules Per Prediction

Power limits how often inference can run. Always-on devices may target 50–100μW average power, which forces careful scheduling. Even efficient models can drain batteries if inference runs too frequently. Power budgets often cap prediction rate before accuracy becomes relevant.

Why Size Kills Deployments

A common failure story looks like this: a 1MB vision model performs well on a workstation, fails on an ESP32, then survives only after compression to 35–45KB. Accuracy drops slightly, but deployment succeeds. Size, not intelligence, decides the outcome.

Constraint-Driven Design Workflow

Successful teams design backward from hardware limits. They lock memory, timing, and power budgets first, then choose architectures that fit. Optimization is planned from day one, not treated as a rescue step later.

| Constraint | Typical MCU | Practical Impact |

| 64KB RAM | Cortex-M4 | Model is often capped below 50KB |

| 10ms budget | 168MHz MCU | Under control-loop limits |

| 100μW avg | Always-on device | Prediction rate is tightly constrained |

Model Optimization Techniques for Embedded Devices

Model optimization is the step that turns a trained model into something an embedded device can actually run. Limited memory, strict timing, and power budgets force engineers to reshape models so they fit real hardware. In TinyML, optimization determines whether a model ships or stays in a lab. Here’s how:

Model optimization is the step that turns a trained model into something an embedded device can actually run. Limited memory, strict timing, and power budgets force engineers to reshape models so they fit real hardware. In TinyML, optimization determines whether a model ships or stays in a lab. Here’s how:

Quantization: Reducing Numerical Precision

Most models are trained with 32-bit floating point values, which are expensive for embedded hardware. Quantization converts these values to lower precision, usually 8-bit integers. This sharply reduces memory usage and compute cost. The tradeoff is minor numerical error, which many embedded workloads can tolerate.

Pruning: Removing Excess Capacity

Trained models often contain parameters that contribute little to final decisions. Pruning removes these weights while keeping output behavior intact. Engineers commonly reduce model size by 50 to 90 percent to reduce memory pressure and execution time.

Knowledge Distillation: Shrinking Behavior, Not Structure

Distillation trains a smaller model to mimic the output of a larger one. The larger model learns complex patterns first, then transfers that behavior to a compact model. This approach often preserves decision quality better than aggressive pruning alone.

Operator Fusion: Cutting Runtime Overhead

On embedded processors, memory movement costs more than computation. Operator fusion reduces intermediate data storage by combining operations. This shortens execution paths and lowers energy usage during inference.

Hardware-Aware Architecture Design

Effective optimization accounts for the target device from the start. Model structure is shaped around instruction support, memory layout, and execution limits. This approach is critical for on-device machine learning, where inefficiency quickly breaks deployment.

Optimization Tradeoff Framework

Every optimization involves compromise. Accuracy, latency, memory usage, and power consumption must be balanced based on system goals. Optimization succeeds when tradeoffs are chosen deliberately, not blindly.

Embedded ML vs Cloud-Based AI

To fully understand machine learning in embedded systems, it is also important to compare it with cloud-based AI. Both approaches solve similar problems, but they operate under very different assumptions around latency, cost, privacy, and reliability. This comparison helps clarify when embedded ML is the right choice and why its role is distinct rather than interchangeable with cloud AI.

| Metric | Embedded ML | Cloud-Based AI |

| Latency | Less than 10 ms, processed locally on the device | 100–500 ms round-trip due to network and server hops |

| Data privacy | Raw data stays entirely on the device | Data must be uploaded for inference |

| Reliability | Operates offline without dependency on connectivity | Fails or degrades when network is unavailable |

| Cost at scale (10K devices) | Near-zero per inference after deployment | Ongoing per-request compute and bandwidth cost |

| Scalability limit | Constrained by MCU memory and compute | Scales with cloud GPUs and infrastructure |

| Power usage | Optimized for low-power, always-on operation | Power cost shifted to data centers |

| Update model | Firmware or model updates are pushed selectively | Centralized model updates on the server |

Common Challenges and Failure Modes in Embedded ML

Embedded ML systems often look solid during testing but behave differently once deployed. Understanding failure modes is essential when working with machine learning in embedded systems, because most problems appear only after weeks or months in the field. These failures can be:

Embedded ML systems often look solid during testing but behave differently once deployed. Understanding failure modes is essential when working with machine learning in embedded systems, because most problems appear only after weeks or months in the field. These failures can be:

Sensor Drift and Environmental Change

Sensors rarely behave the same over time. Temperature shifts, humidity, vibration, and component aging slowly change signal characteristics. Models trained on clean, early data assume stable inputs. Once drift sets in, predictions degrade even though the code and model remain unchanged.

False Positives and False Negatives

Too many false positives cause alert fatigue, and users start ignoring the system. Too many false negatives mean missed events. Threshold tuning that worked in testing often fails under real noise and usage variation, directly affecting trust.

Overfitting and Dataset Bias

Even balanced data can carry hidden bias when collected in controlled settings. Models trained on such data learn narrow patterns, causing performance to drop sharply when exposed to diverse environments and unpredictable field inputs.

Model Degradation Over Time

Performance can decay without any software changes. Hardware aging, shifting usage patterns, and gradual sensor changes all contribute. Without periodic retraining or recalibration, embedded ML systems slowly lose reliability.

Why These Failures Are Hard to Detect

Most failures are silent. Systems keep running, metrics look stable, but confidence and decision quality drift. Monitoring accuracy alone is not enough. Production systems need visibility into confidence trends and error patterns to catch problems early.

If you don’t want these failures to occur during operation, get expert machine learning development service from Webisoft and ensure optimal service of ML in the embedded system.

When Embedded Machine Learning Is the Wrong Choice

ML isn’t the right solution for every embedded problem. Applying machine learning for embedded systems where simple logic would suffice often increases complexity without improving reliability. Knowing when to avoid ML is a sign of sound engineering judgment, not a limitation.

- Simple deterministic control logic: When thresholds, timers, or state machines fully describe behavior, ML adds complexity without benefit.

- Hard real-time and safety-critical loops: Systems such as braking, steering, or medical support require guaranteed timing and predictable outputs. Probabilistic decisions and variable execution paths introduce risk and complicate certification.

- Long-term maintenance and update risk: Embedded ML requires retraining, monitoring, and validation. Devices that can’t be updated over time suffer silent performance decay, reducing reliability.

- Choosing simplicity over overengineering: ML should solve problems rules cannot. When simple logic works, it delivers higher reliability with less operational burden.

The Future of AI in Embedded Systems

Over the next few years, AI in embedded systems will mature from experimental deployments into a standard design consideration. Here’s what people are expecting as future trend in TinyML:

Over the next few years, AI in embedded systems will mature from experimental deployments into a standard design consideration. Here’s what people are expecting as future trend in TinyML:

AI Considered at System Design Time

Embedded teams will plan AI usage earlier in the design process. Instead of adding models after firmware is complete, AI requirements will influence hardware selection, memory layout, and timing budgets from the start.

Smarter Models on the Same Hardware

Progress will come from efficiency, not hardware upgrades, as models are forced to fit within fixed MCU memory, timing, and power budgets. Model architectures will continue to improve, allowing more capable behavior within the same memory and power limits. Doing more with existing microcontrollers will become an expectation.

Embedded AI Integrated Into Firmware Lifecycles

Models will be treated like firmware components. Versioning, validation, and rollback processes will apply equally to code and models.

Growth of Edge AI Beyond Simple Detection

Edge AI will move beyond basic classification tasks. Embedded systems will handle richer context by combining multiple sensor inputs inside firmware, enabling local decisions without cloud dependency or additional hardware.

Clearer Division Between Edge and Cloud

Hybrid architectures will stabilize. Embedded devices will handle time-critical inference, while cloud systems focus on training, analytics, and fleet-level insights. The debate between edge and cloud will give way to clearer role separation.

Reliability Becomes the Primary Measure of Success

Future adoption will be driven by stability in the field. Teams will prioritize consistent behavior, drift monitoring, and controlled updates over benchmark accuracy. AI value will be judged by long-term reliability.

How Webisoft Builds Reliable Embedded Machine Learning Solutions

Webisoft provides end-to-end support for teams looking to deploy machine learning models directly on embedded hardware. The focus is on building systems that fit device constraints, behave predictably in production, and remain maintainable after deployment. Here’s how Webisoft helps you:

Webisoft provides end-to-end support for teams looking to deploy machine learning models directly on embedded hardware. The focus is on building systems that fit device constraints, behave predictably in production, and remain maintainable after deployment. Here’s how Webisoft helps you:

Embedded ML Feasibility and Hardware Assessment

Webisoft evaluates whether ML is appropriate for the target device and use case. This includes reviewing memory limits, timing constraints, power budgets, and hardware capabilities. When rule-based logic is a better fit, that recommendation is made early to reduce risk.

Sensor Data Strategy for Embedded Environments

They help teams collect, clean, and validate sensor data under real operating conditions. Noise, drift, and imbalance are addressed upfront so models reflect how devices behave in the field, not just during controlled testing.

Model Development and Optimization for Devices

Models are designed with deployment in mind from the start. Webisoft applies optimization techniques such as quantization and compression to ensure models fit within memory and latency limits.

Firmware Integration and On-Device Validation

Webisoft integrates ML models directly into embedded firmware. Inference behavior is tested alongside control logic to validate timing, memory usage, and system stability under load.

Deployment Support and Long-Term Maintenance

Webisoft supports deployment workflows, versioning, and update strategies. Drift handling and controlled updates are planned so embedded ML systems remain reliable over time. Get a machine learning consultancy from Webisoft to evaluate whether embedded ML fits your system and how to ensure production reliability.

Build machine learning systems for embedded devices with Webisoft.

Discuss firmware-level ML design, optimization, and production challenges with our team at Webisoft.

Conclusion

To sum up, machine learning in embedded systems succeeds only when it’s treated as a system design problem, not a modeling exercise. Real value comes from aligning data, hardware limits, firmware behavior, and long-term reliability. Use ML where rules break down, design for constraints early, and plan for behavior changes after deployment. With this approach, embedded ML becomes a practical solution rather than unnecessary complexity.

FAQs

Here are some commonly asked questions regarding machine learning in embedded systems:

What programming languages are commonly used for embedded machine learning?

C and C++ are most common because they offer low-level control and predictable performance. Python is typically used only during training and model preparation, not on the embedded device itself.

Can embedded machine learning work without an operating system?

Yes. Many embedded ML systems run on bare-metal firmware without an operating system. Models execute inside deterministic loops alongside control logic, which reduces overhead and improves timing predictability.

Is embedded machine learning suitable for battery-powered devices?

Yes, if designed carefully. Inference frequency, model size, and power states must be managed tightly. Poorly optimized models can drain batteries quickly, while optimized ones run efficiently for long periods.

What hardware is required for embedded machine learning?

Most embedded ML applications run on microcontrollers with limited RAM and CPU power. Dedicated AI hardware is optional. Success depends more on model optimization than on high-performance components.

Do embedded systems need the internet for machine learning?

No. Embedded machine learning runs locally on the device. Models perform inference without internet access, making the system faster, more private, and reliable even in offline or remote environments.